The number of new crown patients is increasing every day, and the sporadic cases in various countries are a fuse that may spread the epidemic again. Therefore, everyone still feels that it is very necessary to wear a flat mask. For consumables such as flat masks, fast production and stable production are required. So which is the best high-speed flat one-to-one mask machine, and how much can the production capacity be achieved?

A good machine, looking for a big brand, this is a well-known saying in any industry, a guide to preventing pits. How did the brand come from? Once the brand is big, it is valuable, and doing something that damages the reputation of the brand is not worth the loss. The same is true for the brand manufacturers of high-speed plane one-to-one mask machines, so when choosing a high-speed plane one-to-one mask machine, you must remember to choose a big brand.

The high-speed plane one-to-one mask machine manufacturer with a good brand is also more reliable in after-sales service. The high-speed plane one-to-one mask machine involves the debugging of the machine and the training of workers, and if there is a problem with the machine in the later stage, is the after-sales service professional enough? timely question.

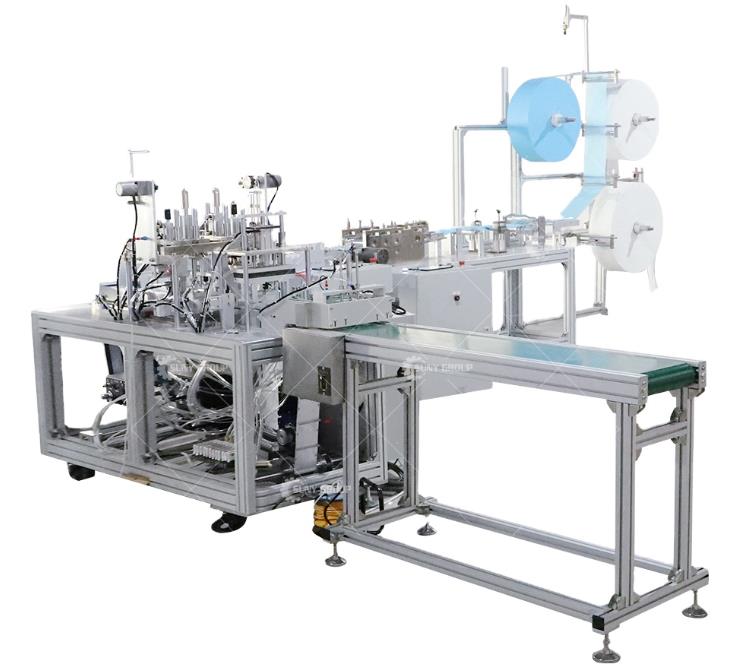

In terms of production capacity, according to the different production solutions proposed by their respective manufacturers, there are many designs of high-speed plane one-for-one mask machines on the market. , is to connect a mask body making machine with a mask earband welding machine. When the mask body is made, it is sent to the mouth and earband welding machine by a conveyor belt for welding the earband part. A complete earloop mask can be completed, with a production capacity of 120-130 Pcs per minute.

The high-speed plane one-to-one mask machine can realize the fully automated production of plane masks, mainly including coil material feeding, folding and pressing, nose bridge rib feeding, mask forming, mask cutting, ear strap feeding and welding, finished product cutting and other processes. To complete the entire production process from raw materials to finished masks, one person can watch multiple machines, with high production capacity and low cost. Now the price of one-to-one mask machines for high-speed planes has also dropped, and it can be said that it is a good time to start. .

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231