1000-5000kg/h

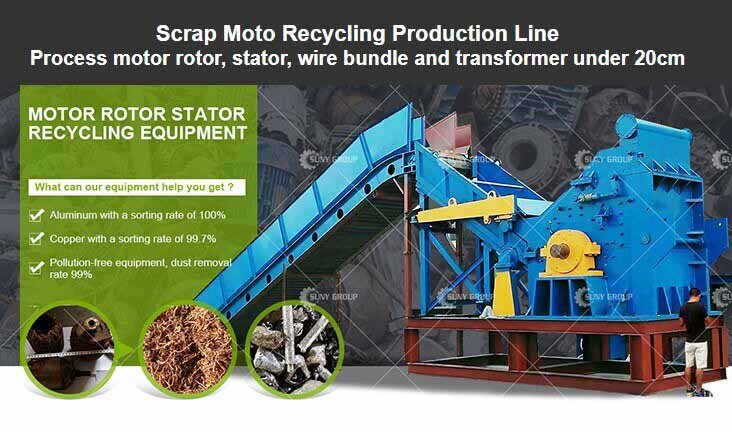

Deal with motor stator which below 20cm, lines, and small transformer, etc

Copper,Iron,Other mixtures

SEND EMAIL: sunymachine@gmail.com

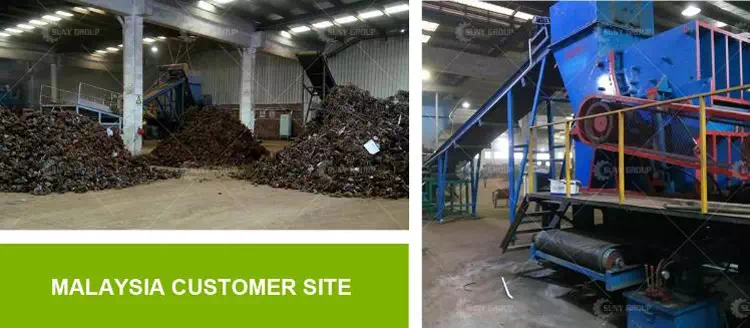

1. The Automatic Scrap Motor Rotor Stator Shredding Separating Production Line can process scrap electric rotor, stator, wire bundle and transformer from household appliances, electric tools, etc. After processing, you can get copper, iron and non-metal.

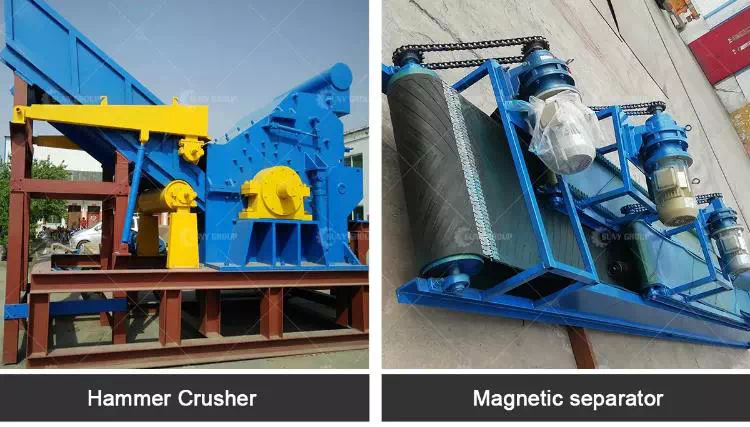

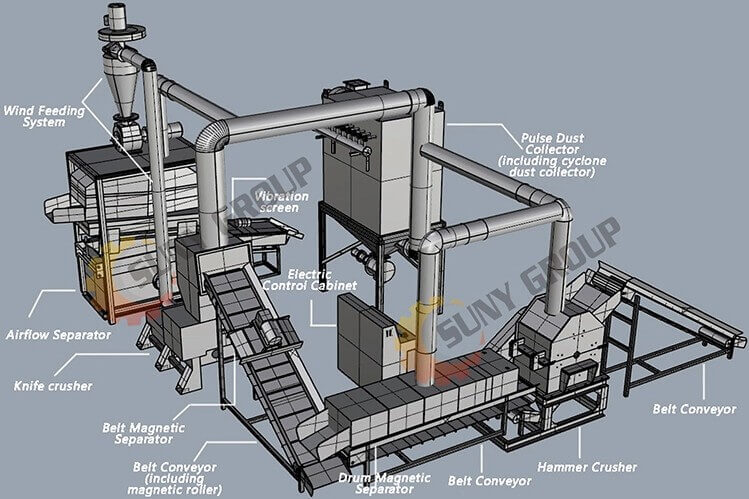

2. It mainly includes hammer crusher, knife crusher, magnetic separator, air separator, pulse dust collector and other accessory machines.

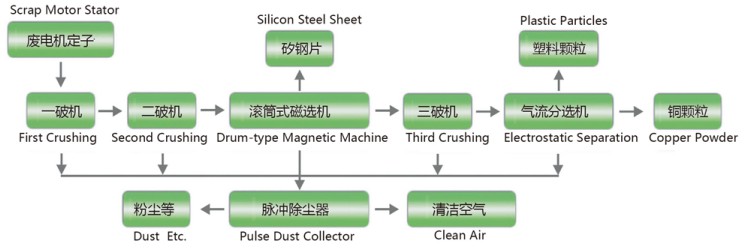

Physical way to recycle the scrap motor stator, controlled by PLC. The manually selected stators, coils are transported to first crusher, second crusher, then through magnetic separator to separate iron and copper. The copper mixture is transferred to grinder to get smaller granules, then to air separator to get purifier copper granular. The machine can reach a considerable economic benefits. The dust caused by crush and separation will catched by pulse dust collecting system, which will prevent the environment from dusts pollution. The machine is meet the standard GB16297-1996.

1.Controlled by PLC, the whole machine works in stable way

2.Easy construction, stable running, little vibration and low noise

3.First crusher is equipped with two axis, with the advantage of low noise, large torque and big crushing

4.The shredder use the special alloy blades, own the ability to shredding, pull-apart, and extruding, cacrush different materials easily

5.The second crusher is tear-type, consist of tinny cutter and cylinder shank, which reduce the cost of wearing parts. The diameter of the axis in second grinder is 360mm, making bigger compact on the material. The blades adopt the minitype cutting bit and the column cutter bar, and reduce the wearing parts cost.

6.netic separator is made of two roller separators, to make sure the separate rate up to 97%: and the eparator make the copper more clean and high purity

7.Dedusting separation of pulse dust catcher can reach 99, 99%. Not only catch the dust, but also meet the environmental requirements(gb16297-1996)

| Model | Power | Size(m) | Capacity |

| MR-1000 | 177kw | 25x6x6 | 1t/h |

| MR-2000 | 303kw | 40x6x6 | 2t/h |

| MR-3000 | 345kw | 45x6x6 | 3t/h |

| MR-5000 | 493kw | 50x10x6 | 5t/h |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

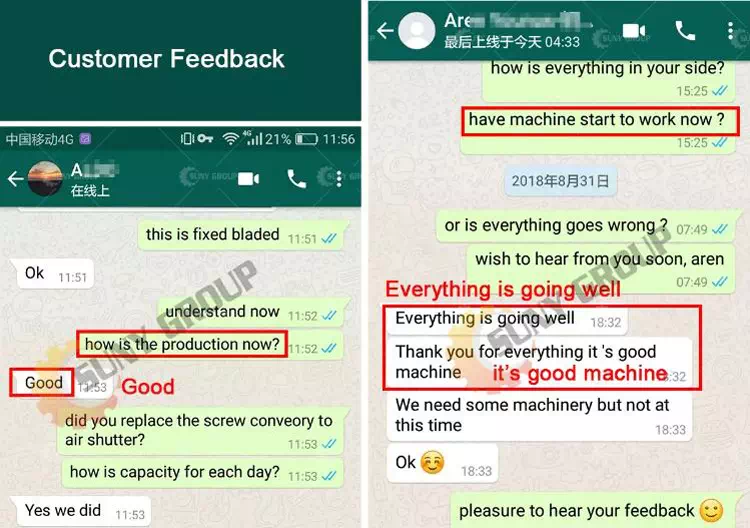

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.