30-40T/Day

All kinds of lead-acid batteries, such as automotive battery, truck battery, electric bicycle battery, etc.

lead and plastic shell

SEND EMAIL: sunymachine@gmail.com

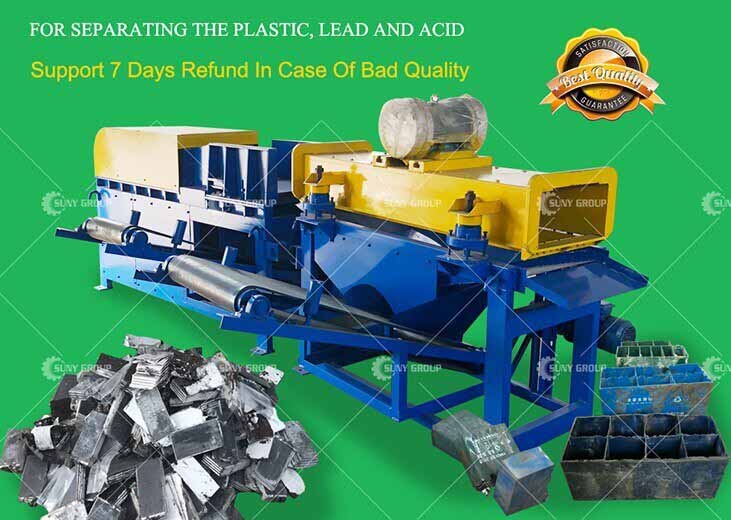

Electric Car Battery Dismantling Equipment Lead Acid Battery Recycling Machine is suitable for recycling all kinds of lead-acid batteries, such as automotive battery, truck battery, electric bicycle battery, etc.

There are different alternatives to the final disposition of batteries: landfill, incineration and recycling. The number of processes for battery recycling have increased over the last few years, mainly because of the environmental impact caused by their disposal.

In world as well as China there is a strict limit for the pollution industry. As for this situation, we designed the All-In-One lead acid battery recycling machine for lead battery separating and recycling, which is few pollution and easy to operate.

The final products of Electric Car Battery Dismantling Equipment Lead Acid Battery Recycling Machine are lead and plastic shell.

WASTE LEAD ACID BATTERY RECYCLE MACHINERY

The Electric Car Battery Dismantling Equipment Lead Acid Battery Recycling Machine is environmental protection. Firstly the scrap lead acid battery will be separated by the "Battery Separating machine". The final produts of separation section is plastic, lead, acid. The coarse lead can be refined by Smelting Section.

And then you can choose the Cupola Furnace to get the refined lead ingot if you want to get deeply recycle. As for the Smelting Section, there is also Air Pollution Purify System to meet the environmental protection policy.

1. Suitable structure and layout, stable performance, Environmental friendly production line.Separating section: pure phycisal separation.Smelting section: Air Pollution Purify System Technology is the guarantee, Quality is the life; Service is the foundation, Brand is the target.

2. Production line can adopt to different venues, Production line installation is convenient, Full automatic working, save labor.

| Size(MM) | Power(KW) | Capacity(T/DAY) |

| 2850*800*2100 | 7.5 | 30-40 |

| Working Performance | ||

| Raw Material | Waste Lead Acid Battery | |

| Feedin Port | One Feedin Port (feedin size could be made as required) | |

| Operator Required | 2 People is enough | |

| Option | ||

| 1.Standard model machine body made of durable steel,stainless steel acceptable as optional choice 2.OEM acceptable,entire machine could be made according to diferent size of baeries. 3.One year warranty,one complete set of wearing parts delivery with machine for free. 4.Battery shell cleaning and crush system available as option. | ||

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.