800-1000kg/h

soft package battery, cellphone battery, shell battery, cylindrical battery etc

graphite powder, cobalt acid lithium, aluminum and copper.

SEND EMAIL: sunymachine@gmail.com

Battery specialists and environmentalists give a long list of reasons to recycle Li-ion batteries. The materials recovered could be used to make new batteries, lowering manufacturing costs.

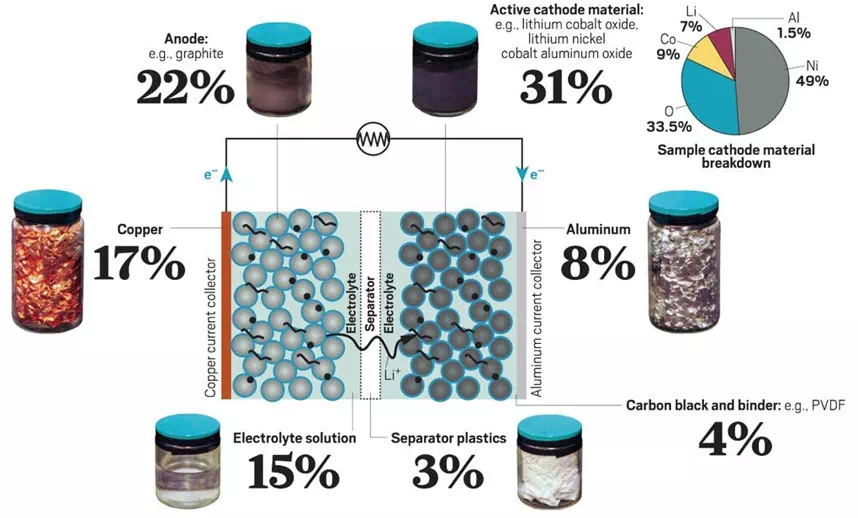

According to the material composition analysis of lithium-ion battery, it contains a lot of valuable metals. Take one kind of the lithium ion battery as an example, which contains 31% cathode material, 22% anode material, 17% copper, 8% aluminum, 4%% plastic paper etc.

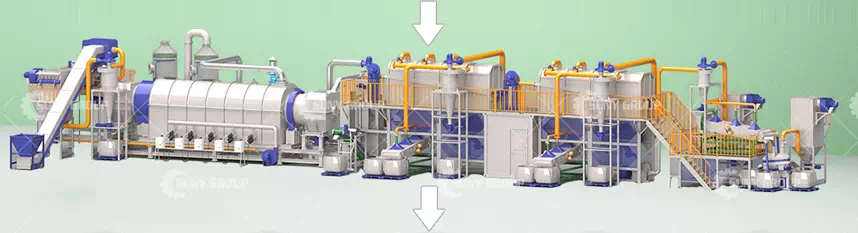

Our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries. The lithium battery recycling production line is used for dismantling and recycling the Soft package battery, cellphone battery, Shell batter Cylindrical battery etc. The final products of this plant is Graphite powder, Cobalt acid lithium Aluminum and Copper.

The lithium-ion battery recycling production line is used for recycling the cylindrical cells,prismatic cells, pouch cells negative plate,positive plate etc.

The final products are black mass, aluminum granule, copper granule, plastic, steel shell and separator plastic etc.

| Output | Size |

| Black Mass | About 120-150 mesh |

| Aluminum granule | About 3 mm |

| Copper granule | About 3 mm |

| Shell Material | About 2-3 cm |

The carbonized anode and cathode materials can effectively peel off the anode and cathode powder from the metal after crushing, and the metal and anode powder can be preliminarily separated by vibration screening based on the size difference and shape difference between particles.

The complete set of equipment operates under negative pressure, without dust spillage, and the oveall separation efficiency can reach over 98%.

| Feature Item | Indicator Requirments |

| Recovery Rate of Metallic Aluminum | 98% |

| Powder Recovery Rate | 98% |

| Content of Powder In Metal Aluminum | 2% |

| Content of Metallic Aluminum In Powder | 2% |

| Other | Contain dust collecter with not pollute |

| Qualified Rate | 99% |

| Failure Rate | 1% |

| CMR | ≥1.67 |

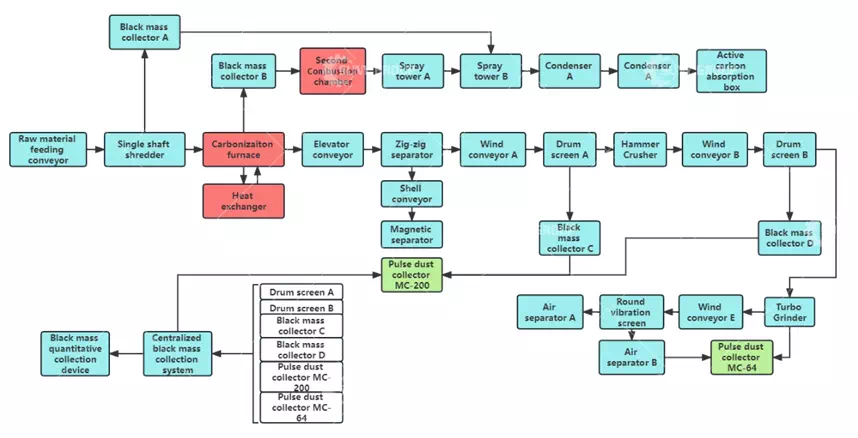

First, the scrapped lithium battery is discharged. The discharged scrap lithium battery is crushed to about 10cm, and then enters the carbonization furnace through a conveyor. During the carbonization process, the separator is directly carbonized, the electrolyte is pyrolyzed and gasified, and the adhesive is gasification. Because the furnace is almost a closed space, it meets anaerobic conditions, so that the diaphragm, adhesive, and electrolyte are heated up inside the carbonization furnace for pyrolysis and gasification. The generated flue gas passes through the recovery pipe and flue gas purification system to achieve reciprocation. Effect of cyclic thermal decomposition. During the initial carbonization preheating, the plastic diaphragm begins to carbonize and pyrolyze, the electrolyte reaches gasification, and finally pure copper, aluminum and black powder are obtained, and then the aluminum and copper powder are separated through a screener, a crusher, and an electrostatic separator. A magnetic separator is added in the middle to separate the iron shells.

Shredder: shred lithium batteries into smaller pieces

Carbonization furnace: Carbonization and pyrolysis of scrap lithium batteries

Grinder: For the grinding of the crushed materials

Separation machine: Separate the materials after being ground

Collector: Collect and release the dust

Pulse purifier (air cleaner): Clean all the dust produced during the operation of the whole system

Classifying screen: Screen the materials sorted by the separation machine, and screen out of larger metal materials

Magnetic machine: Separate nickel from the metals

Gravity separator: Separate those finer materials got from the screening machine and separate the metal completely

High-pressure blower: Keep the whole system in a negative state so as to collect the materials and purity the air

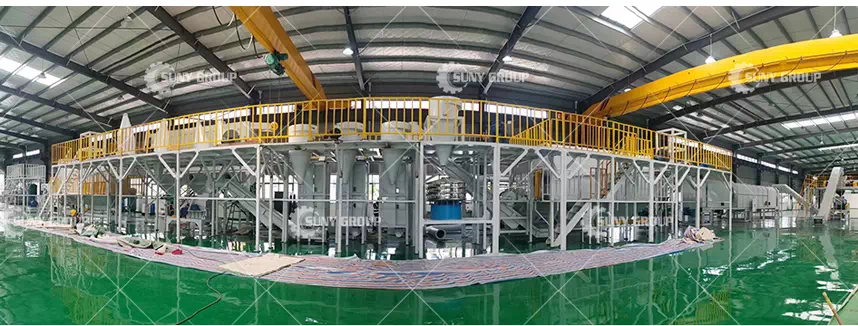

To ensure the machine performance, for every machine before leave our factory,no matter its single machine or big production line, we all connecting whole line,buy raw materials to trial running, to ensure every part are up to standard.

We offer on-site installation services to ensure the smooth functioning of the equipment in the field.

Our comprehensive technical training program equips customers with in-depth knowledge of equipment operation, primary troubleshooting techniques, and common problem-solving methods.

Our commitment to lifelong technical support ensures continuous assistance and guidance for the machine throughout its lifespan.

| Model | Power(KW) | Overall Dimension(MM) | Capacity(Kg/H) |

LIBR-1000 | 361 | 51000*10000*7500 | 800-1000 |

| LIBR-2000 | 740 | 56000*16000*8000 | 800-1000 |

NOTE:

Working voltage:380±10V(415V ,440V also can be custom);

(If you want more detailed parameters and quotations, please contact us)

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.