Due to different processing techniques, the microstructure of copper foil materials is different. Observing the cross section of the material under a 1000x microscope, the copper atomic structure of the rolled material showed irregular layered strong crystals, and it was not easy to form cracks and good bending performance for recrystallization after heat treatment; while the electrolytic copper material showed columnar crystals in the thickness direction Microstructure, easy to crack and break when bending.

Aiming at the shortcomings of electrolytic materials, some material suppliers have developed high-delay electrolytic materials, which is to recrystallize copper atoms by processes such as heat treatment of the material after conventional processing, but its columnar structure remains. Therefore, there is still a big gap between the flexibility and the rolled copper foil.

2. Pros and cons

Conductivity: The conductivity of rolled copper is weaker than that of electrolytic copper.

Ductility: The ductility of rolled copper materials is better than that of electrolytic copper materials. The elongation of rolled materials reaches 20-45%, while that of electrolytic copper materials is only 4-40%.

Bendability: Measurement of bending deflection (all samples are 35µm thick and heat treated at 200 ° C / 30 minutes, radius of curvature is 2.5nn, stroke is 25mm), rolled copper foil is 1,600 times, special electrolytic copper foil is 5233 times , The standard electrolytic copper foil is 2560. From the results of testing and evaluation of flexibility, it can be seen that the flexibility of rolled copper foil is about 4 times higher than that of general electrolytic copper foil. Its deflection reliability has an overwhelming advantage.

Manufacturability: The electrolytic copper material is formed by electroplating, and its crystalline structure of copper particles can easily form vertical line edges during etching, which is very conducive to the production of fine wires.

Flatness: Due to the high density of the rolled copper foil, its production method determines that its surface has uniform smoothness. The surface roughness (Rz) of the prepared rolled copper foil green foil is only 1 μm, while the surface roughness Rz of the general electrolytic copper foil green foil is 5 μm.

3.Other differences

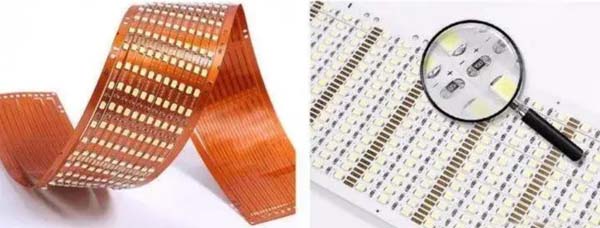

1) Color difference: The rolled copper is yellow, and the electrolytic copper is red.

2) Price difference: Due to the complex processing of rolled copper, the unit price of rolled copper is more expensive than electrolytic copper.

3) Differences in crystal structure: The electrolytic copper crystal structure is arranged vertically, and the electrolytic copper molecules are loose and easy to break. The rolled copper crystals are arranged in an overlapping manner. The rolled copper molecules are compact, and the flexibility is as thin as possible. The post-treatment plating surface is bright, but the flexibility is worse than that of pure rolled copper.

As the cost of electrolytic copper is low and the conductivity is good, you can choose electrolytic copper for ordinary PCB board or FPC. For products with low bending requirements (such as key board, module board, 3D static flexible circuit, etc.), you can choose High-strength electrolytic copper is used to replace rolled copper foil materials. Of course, for products with higher reliability requirements (such as slider phone panels, folding phone panels, retractable cameras, etc.), it is better to use rolled copper foil materials.

In addition, due to the good surface roughness of the rolled copper foil, using it as the conductive layer of the PCB can overcome the "skin effect" caused by the current passing through the conductive layer at a frequency above 1GHz, reducing the impedance generated, which is beneficial to the rapid signal transmission. Therefore, in the high-frequency high-speed transmission, fine circuit PCB, in recent years also began to use some rolled copper foil. In addition, based on this advantage of rolled copper foil, even in two-layer FPC, trials of rolled copper foil without surface roughening treatment have even begun.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231