In the process of rapid development of the new energy vehicle industry, the reuse of used lithium batteries will become an important emerging industry, and many technologies and equipment are still in the early stages of development. Regarding the broad prospects for the reuse of waste lithium batteries and power batteries, SUNY GROUP, after more than ten years of research, has developed new technologies for power battery, lithium battery charged dry recycling, designed various power batteries, and lithium battery charged crushing, sorting and recycling. Production process, this technology takes the idea of electrified crushing as the theme, and has the advantages of stable operation, safe production, beautiful appearance, energy saving and environmental protection, large output and labor saving. A complete set of production equipment for charging and recycling lithium batteries.

The processing method of the positive and negative electrode sheets of the lithium battery after the power lithium battery crushing and air separation recovery: the charged lithium battery enters the vibrating feeder according to the anaerobic motion, and enters into the oxygen-depleted crushing. The anaerobic motion evaporates rapidly at high temperature, and the evaporated raw materials enter the sorting system software to sort the plastic film type, the iron type with magnets, and the copper-plastic-steel shell in the rechargeable battery rechargeable battery.

The remaining positive and negative films enter the high-speed friction system software to carry out friction and clearance. The raw materials after clearance are subjected to cyclone sorting, selection and dust removal, and the positive and negative powder, copper and aluminum metal material particles, and plastics are separated. The negative powder is sent to the anaerobic motion cracking system software to carry out anaerobic motion cracking. The natural gas caused by the cracking and the organic waste gas caused by the sorting are comprehensively ignited. Dissolved organic waste gas is used as supplementary oxygen and organic waste gas. The waste gas after incineration treatment is separated from simple organic waste gas, refrigeration, self-spraying, filtering, aerosol, activated carbon honeycomb or activated carbon catalytic reaction to meet environmental protection standards. The water circulation system, which is often required in production and manufacturing (no direct drainage resources), is used. The noise during the production process also conforms to my country's environmental protection regulations. The organic waste gas and natural gas of all air separators are ignited with each other to achieve comprehensive utilization and treatment of organic waste gas.

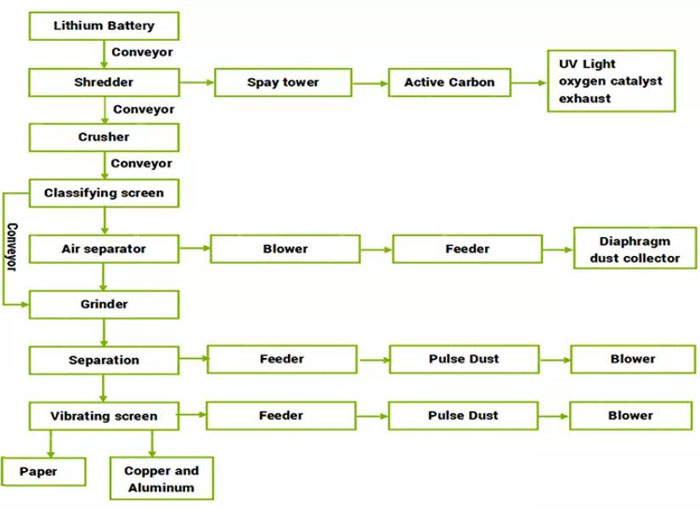

In short, the process of lithium battery crushing equipment is as follows:

Discharge: Set up discharge facilities in the workshop to release the power in the waste lithium battery, and spread the discharged battery to dry naturally.

Dismantling, dismantling the waste lithium battery through the combination of manual and machine, and separating the disassembled casing, aluminum foil, copper pole pieces, etc. according to the material.

Pulverization: The dismantled metal-containing battery materials for subsequent processing are pulverized. The pulverization facility is equipped with a dust collector, which does not pollute the outside world.

Separation: The pulverized battery material pole piece and black powder are separated, and the copper and aluminum foil metal and the black powder are separated to achieve a purity of 99.8%.

With the continuous development and use of automotive power lithium batteries, more and more scrapped lithium batteries need to be recycled effectively and valuable. On the one hand, it does not pollute the environment, and on the other hand, it can also obtain considerable economic value through recycling. SUNY GROUP has perfect technical equipment and rich experience in the recovery and reuse of lithium batteries. Welcome customers to come to consult and cooperate.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231