After the lithium ion battery positive and negative material crushing and recycling equipment crushes the waste lithium battery raw materials, the various materials in the crushed product realize the monomer dissociation, plastic shell, diaphragm paper, copper foil, aluminum foil and other materials, including cobalt lithium metal.

The production line is that the scrap batteries enter the shredder for shredding, and the shredded batteries enter the special crusher for shredding. The positive and negative plates and the diaphragm paper inside the battery are scattered, and the scattered materials enter the collector through the induced draft fan. Then, the dust generated in the crushing is collected and purified by the pulse dust collector. The material entering the collector enters the air flow sorting screen through the closed air device. The diaphragm paper in the positive and negative plates is collected through the air flow and vibration, and the air flow The dust generated by the sorting machine is collected.

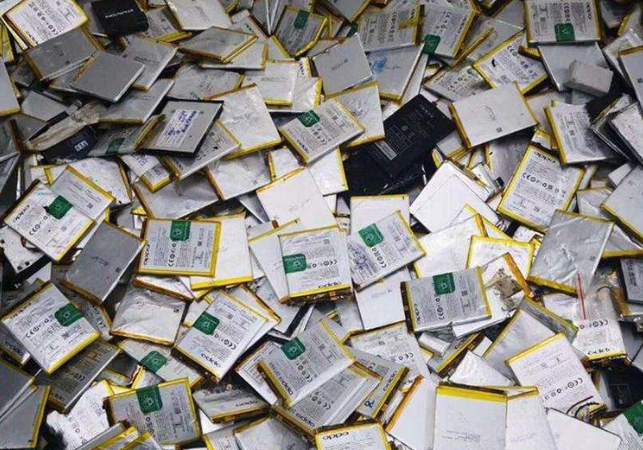

Lithium Battery Recycling Machine

Then, the mixture is separated and recycled using a combined process of hammer crushing, vibrating sieving and airflow sorting to separate and recover the positive and negative electrode components of the waste lithium battery.

The current mechanical separation provides favorable conditions for the later hydrometallurgy. The complete lithium battery crushing and recycling equipment has a simple process and automatic process, which can reduce the scrap rate and recycling rate of waste lithium battery resources.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231