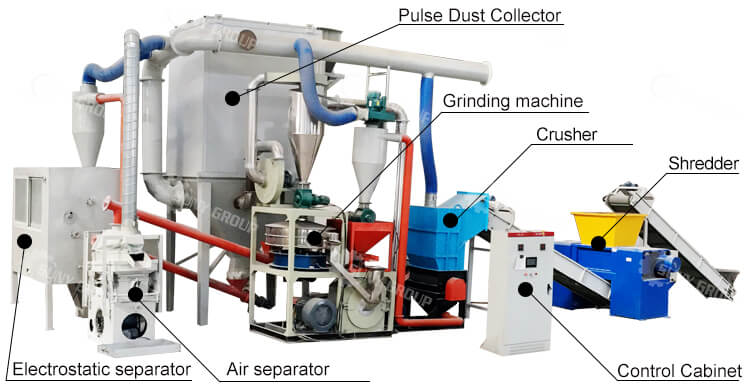

Circuit board crushing and recycling equipment is mainly used for the separation of metals and non-metals in various waste electronic waste, waste circuit boards, circuit boards, copper clad laminates and scraps. Improve the quality of recycled copper and prevent secondary pollution. This production line adopts secondary pulverization for the recycling and processing of waste circuit boards to make it into a mixture of metal and resin fiber powder; and then separates the metal from the resin by wind and electrostatic separation. In order to prevent dust pollution during processing, a pulse dust removal device is added after the air flow sorting process, which effectively solves the problem of dust pollution.

working principle:

The environmentally friendly circuit board recycling equipment uses electrostatic separation technology for metal separation. The principle is to use the difference in the conductivity of materials. In a composite electric field combining high-voltage corona electric field and high-voltage electrostatic electric field, it plays a role in electric and mechanical forces. Next, realize the separation of materials. The attractive force of the static electrode is strengthened to the conductor, and the repulsive force is strengthened to the non-conductor. A high-frequency alternating strong magnetic field is generated on the surface of the separating magnetic roller. When the conductive non-ferrous metal passes through the magnetic field, an eddy current is induced in the non-ferrous metal. This eddy current itself generates a magnetic field opposite to the original magnetic field. Non-ferrous metals (such as copper, aluminum, etc.) will leap forward along the conveying direction due to the repulsive force of the magnetic field, achieving separation from other non-metallic substances, and achieving the purpose of sorting; the main distinguishing criterion is that the material is conductive The ratio value of the ratio and density. The higher ratio is easier to separate than the lower ratio.

Features:

1. Newly added automatic control device makes the whole process flow in an orderly manner, which not only reduces manual operation, but also reduces energy consumption, pollution-free emissions, and improves work efficiency;

2. Good overall performance, with unique effects on computer boards, computer boards, TV boards and other circuit control boards. It is also compatible with the recycling of various circuit boards containing capacitors;

3. This production line is an upgraded product of wind-selected products, with a smaller footprint, and is an ideal production line for recycling waste electrical (line) circuit boards to the present;

4. The whole set of equipment adopts a new type of dust collector, three-in-one dust removal (cyclone dust removal + electrostatic dust removal + static dust removal) without pollution to the air and no exhaust gas emission;

5. The equipment has a neat appearance, flexible installation and convenient operation.

Equipment advantages:

1. Good overall performance, with unique effects on computer board recycling, computer board recycling, TV board recycling and other circuit control board recycling. It is also compatible with the recycling of various circuit boards containing capacitors;

2. This production line is an upgraded product of Type A products. On the basis of Type A, it consumes less power, has no noise, less labor, high automation procedures, and improved efficiency. At the same time, it occupies a smaller area and is a waste electricity (line) circuit board. Recycle to the current ideal production line;

3. The whole set of equipment adopts a new type of dust collector, three-in-one dust removal (cyclone dust removal + electrostatic dust removal + static dust removal), which has no air pollution and no exhaust gas emission;

4. The appearance of the equipment is clean and tidy, and there is no dust bag, which replaces the problems that cannot be solved by traditional dust collectors.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231