SEND EMAIL: sunymachine@gmail.com

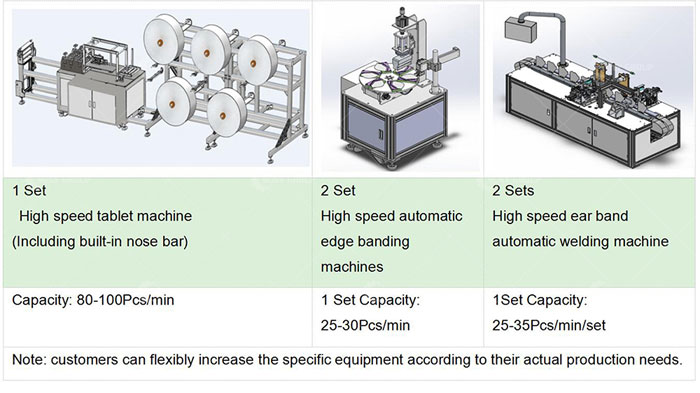

COMPLETE EQUIPMENT COMPOSITION:

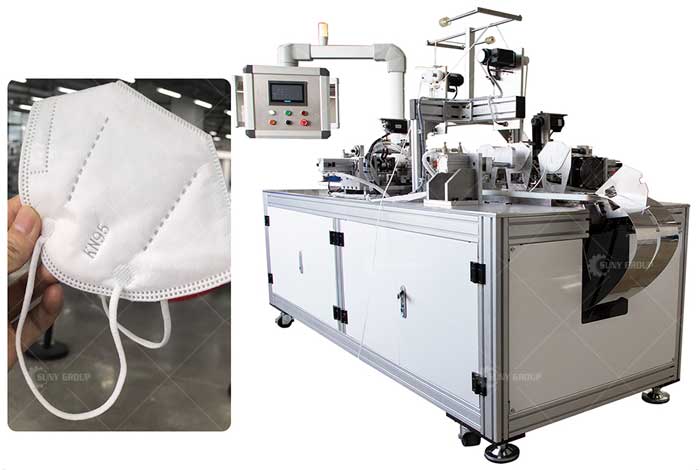

The high-speed film machine adopts ultrasonic welding technology to automatically produce 2-5 layers of butterfly mask body(such as 3M companys 9001, 9002 series masks). Automatically complete the operation, manual feeding and automatic feeding; the included processes include coil feeding, nose beam feeding, mask pattern welding, mask cutting, and main body cutting The equipment produces the main body of the butterfly mask through the cooperation of the feeding system, the fabric forming system, and the nose beam forming and cutting system. In order to meet the market demand, the mold can be simply replaced to adapt to the production of various types of butterfly mask bodies.

| Weight | About 400 KG |

| Dimension | 620mm(L)X1000mm(W)X1600mm(H) |

| Working power | 220VAC土5%,50HZ |

| Equipment power | rated power: about 4KW |

| Compressed air | No |

| Use environment |

Temperature 10-35 C, temperature 5-35% HR, no dust(cleanness not less than 100,000 |

| Capacity | 80-100pcs/min |

| Nose bridge method | Built-in nose bridge |

1. The equipment adopts 6-position automatic rotating platform, with ultrasonic automatic welding technology and automatic edge sealing of mask.

2. The main process includes manual loading, ultrasonic welding and edge sealing, and automatic unloading.

3. Automatic completion of welding process, convenient operation &high yield rate.

4. It can quickly change the positioning fixture to adapt to the production of various types of butterfly masks.

| Weight |

About 100KG |

|

Dmension |

1200mm(L)X800mm(W)x1800mm(H) |

|

Working Power |

220VAC土5%,50HZ |

| Equipment Power |

Rated Power 3.5KW |

|

Compressed Air |

Pressure: O.6mpa-0.7 Mpa |

|

Environment |

Tempreture 10-35 C; Humidity5-35%HR Non dust(Cleanliness greater than class K) |

|

Capacity |

25-30pcs/min |

2. Only one person is needed to operate one device, reducing labor cost.

3. Manual feeding, automatic cutting, automatic welding and automatic blanking are safe and convenient.

4. Automatic welding of butterfly mask lugs can quickly replace positioning fixture to adapt to the production of various types of butterfly masks.

| Weight | 500KG |

| Dimension | 2400mm(L)X800mm(W)x1700mm(H) |

|

Power supply |

220VAC±5%,50HZ |

| Power | 3KW |

| Compressed air |

Pressure: O.6mpa; Flow rate: 200L/min |

| Working environment |

Temperature 10-35 C: Humidity5-35%HR; No dust(clean class more than 100,000 grade) |

| Speed |

25-35pcs/min |

MATERIAL:

| ITEM |

WIDTH (mm) |

| Non-woven cloth(The layer close to the face) | 150 -175mm |

| Non-woven cloth(Outermost layer) | 150~175mm |

| Melt blown cloth layer | 150~175mm |

| Hot air non-woven cloth layer | 150~175mm |

| Specification of nose bar | 3-5土0.2 |

| Ear band | 5-8 |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.