SEND EMAIL: sunymachine@gmail.com

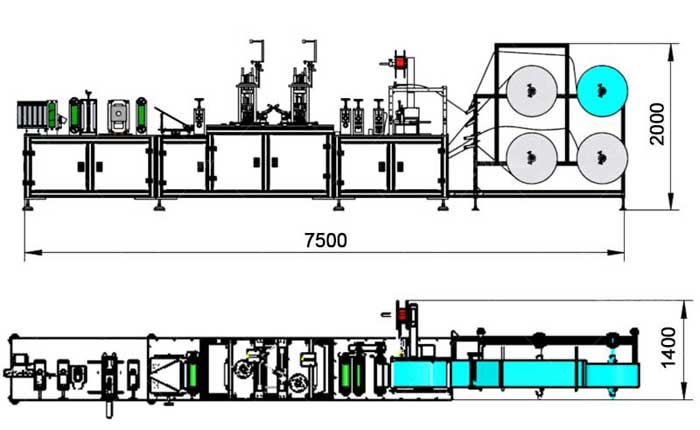

| 【 PRODUCT NUMBER 】ZYN95-60 | 【 VOLTAGE 】220VAC+5% |

| 【POWER】10KW | 【SIZE】7500x1400x2000mm |

| 【YIELD】35 - 45pcs / min | 【WEIGHT】1500kg |

Product specifications: folded size 1 10mmX122mm(You can change the abrasive fine-tuning size)

Product Advantages:

1. The equipment is equipped with Max6 sets of cloth unwinding and a roll diameter of Max600mm;

2. The fabric unwinding adopts the active unwinding method, and automatically unwinds according to the position of the tension roller;

3. Nose bar welding module: including the functions of nose bar unwinding, nose bar leveling, fixed length conveying, cutting and welding;

4. Fabric compound roll welding unit: adopts ultrasonic welding head and steel mold welding method, roller parallelism and position are accurately adjusted during welding, and the welding system has cooling function;

5. Ear strap welding unit: The ear strap welding of this equipment adopts the ear strap type (non-head-mounted), the whole roll is loaded, after driving and tension control, the fixed length is cut, the length of the ear strap is adjustable, and the ultrasonic welding is used. Welding firmly;

6. The equipment has printing function, the position of the printing and dyeing logo can be adjusted, and the content needs to be provided by Party A in advance;

7. The material driving unit adopts a servo motor to control the main driving roller to drive the cloth, running smoothly, and the pressure is precisely adjustable;

8. Folding forming unit: adopt adjustable triangle plate with adjustable height and angle to ensure that the mask is neutrally folded in half.

9. Forming welding unit: ultrasonic welding is used, the welding is firm, the pattern is clear, the pressure of the welding system is adjustable, the welding system has a cooling device, and the technical parameters of the ultrasonic welding system are adjustable;

10. Forming and cutting unit: rolling cutter wheel, cutter pad wheel, adjustable pressure, cutting force material: high speed steel.

11. Waste separation unit, the waste automatically falls into the frame; 12. Control system: The equipment includes PLC control system and touch screen operating system.

MAIN CONFIGURATION:

ABOUT DELIVERY:

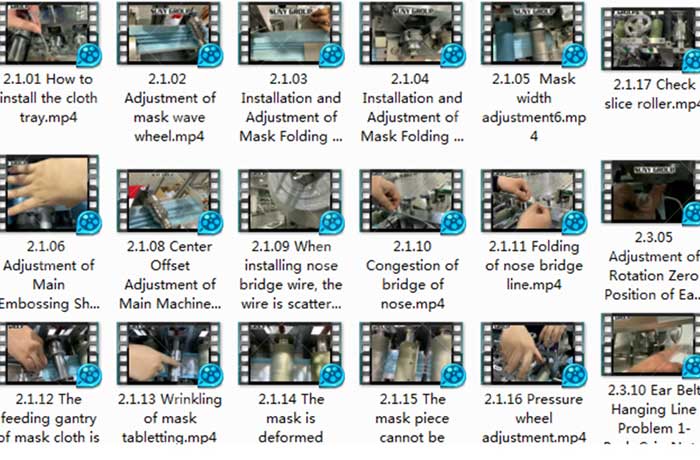

ABOUT AFTER SALES:

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.