With the rapid renewal of electronic products, electronic waste (E-Waste) has become a major challenge in the field of global environmental protection. The appearance of automatic E-waste dismantling and recycling equipment provides an efficient and environmentally friendly solution to this problem. The equipment not only efficiently dismantles and recycles the valuable materials in e-waste, but also ensures that the environmental impact of the process is minimized.

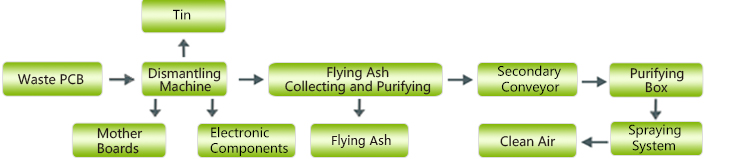

The workflow of the automated e-waste dismantling and recycling equipment consists of several key steps: component dismantling, separation processing, and material recovery.

PCB Component Dismantling Machine Working Process

Automated dismantling equipment begins with the initial dismantling of discarded electronic products. These wastes are usually composed of a variety of materials such as plastic, metal, glass, etc., and need to be processed through efficient dismantling technology. Through automation, the equipment quickly removes the casing, connecting parts and internal components, and separates different types of waste materials. This process is mechanized to ensure that the dismantling process is efficient and precise.

After dismantling, the waste is further separated from the material by automatic sorting equipment. Sorting technologies include magnetic separation, electrostatic separation, airflow separation, and other methods that can efficiently separate materials such as metals, plastics, glass, and paper. These materials can be recycled and reused after careful processing. Metals such as copper and aluminum, plastics, and other renewable materials can be reintroduced into the production chain after purification, maximizing the use of resources in e-waste.

The advantages of automated e-waste dismantling and recycling equipment over traditional manual dismantling methods are its efficiency, precision, and environmental friendliness. First of all, the automated system can greatly improve production efficiency and reduce labor costs. Through intelligent operation, the equipment is able to operate efficiently around the clock without being affected by human factors. The dismantling speed is several times faster than manual operation, and at the same time, it can ensure that the dismantling process does not cause unnecessary damage to the material and maintain its recycling value.

With the rapid renewal of electronic products worldwide, the amount of e-waste has shown an alarming growth trend. E-waste not only contains a large number of hazardous substances but also contains a wealth of recyclable resources. Through effective recycling treatment, it can maximize the use of waste metals, plastics, glass, and other materials, reduce the waste of resources, and reduce environmental pollution. The introduction of automatic e-waste dismantling and recycling equipment not only improves recycling efficiency and reduces costs, but also plays an important role in protecting the environment.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231