In the electronic waste recycling industry, electronic components on printed circuit boards (PCBs) often contain high material value, but they also present challenges such as difficult disassembly, high labor costs, and unstable efficiency. Automated PCB component disassembly equipment is a key piece of equipment designed to address these practical problems. Its core function is to achieve efficient separation of components from the circuit board without damaging the substrate structure.

I. Overall Process and Workflow

The processing logic of the automated PCB component disassembly machine is simple yet highly practical. After entering the equipment, the waste circuit boards are subjected to controlled heating or physical detachment to bring the solder to a state suitable for separation. The components on the board surface then automatically detach under gravity or mechanical force. The entire process eliminates the need for manual removal of each component, significantly improving processing efficiency and reducing damage to the circuit board substrate. After disassembly, the components and bare boards can be sent to subsequent recycling or processing stages, laying a solid foundation for the entire PCB recycling process.

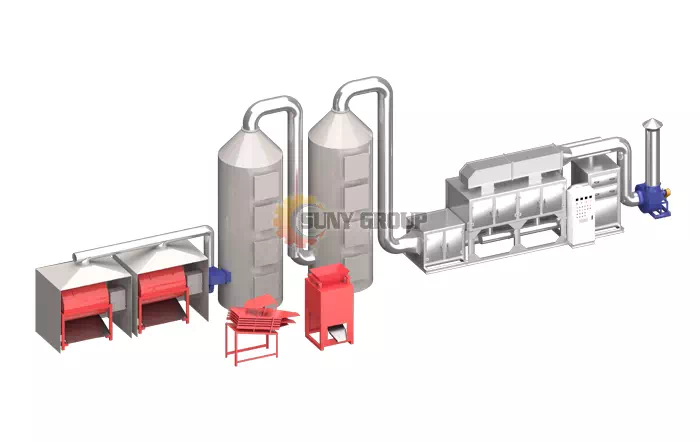

Automatic Components Dismantling Machine for PCBs

II. Core Equipment Structure and Technical Features

The equipment's structural design emphasizes stability and controllability. The heating system provides uniform temperature distribution, adapting to the soldering structures of different types of PCBs and preventing localized overheating that could lead to board deformation. The transmission and conveying systems are well-coordinated, ensuring continuous operation of the circuit boards during disassembly and reducing the risk of jamming and downtime. The equipment can also adjust operating parameters according to actual needs, meeting the processing requirements of various PCB specifications. Compared to manual or semi-automatic disassembly methods, automated equipment offers significant advantages in consistency and safety.

III. Application Value and Recycling Significance

Automated PCB component disassembly equipment is widely used in electronic waste recycling companies, resource recovery centers, and the front-end processes of PCB recycling production lines. By disassembling components in advance, it not only reduces the difficulty of subsequent crushing and sorting but also helps improve metal recovery rates and reduce unnecessary material loss. The equipment's stable operation and low labor requirements help recycling companies control long-term operating costs. As electronic waste recycling increasingly moves towards large-scale and standardized operations, this type of automated disassembly equipment is becoming an indispensable part of the PCB recycling system.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231