Demand for lithium-ion batteries is growing rapidly due to their widespread use in electric vehicles and electronic devices. Therefore, the need for efficient and environmentally friendly Li-ion battery recycling machines and systems has become crucial. This article provides a comprehensive guide to lithium-ion battery recycling machines and systems, discussing the challenges, innovations and future of the industry.

The rapid growth of lithium-ion batteries and the sudden rise in market demand have led to a significant increase in the production of used batteries. In addition, some waste is generated during the battery manufacturing process. Recycling such waste in an environmentally friendly, economical, and efficient manner can not only eliminate the risks it poses to the environment and public health, but also provide raw materials for the production of lithium-ion batteries, further reducing resource usage.

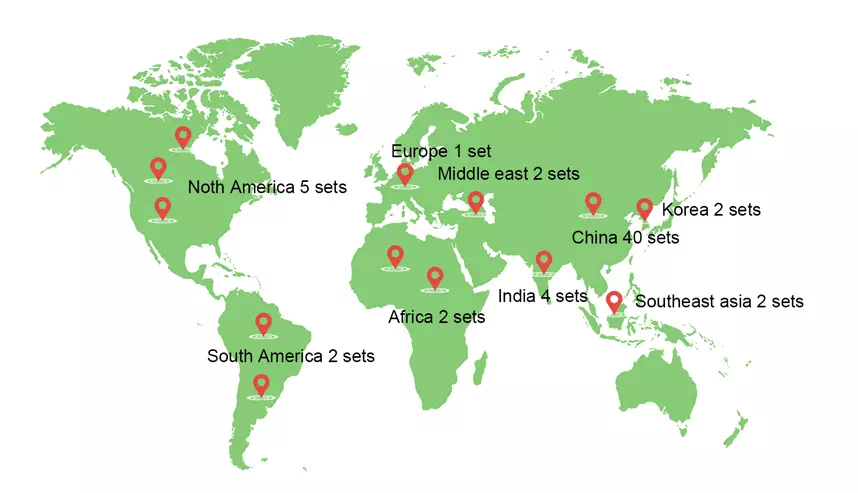

In order to effectively recycle waste lithium-ion batteries, a special production line and complete sets of equipment for crushing and sorting waste lithium-ion batteries with advanced technology are being developed and constructed. SUNY GROUP, as an experienced lithium battery recycling solution design and equipment manufacturer, has provided innovative lithium-ion battery shredding and separation plants to many customers to effectively and sustainably process used lithium-ion battery waste.

Due to the complex composition of spent lithium-ion batteries, which include metals such as nickel, cobalt, manganese and lithium, as well as electrolytes and organic solutions, there are several challenges in recycling used lithium-ion batteries. Improper disposal of these batteries can cause significant harm to the environment and waste valuable resources. Moreover, due to the chemical reaction inside the battery, the ambient temperature rises, and thermal runaway can easily lead to safety hazards such as combustion, fire, and explosion. Therefore, the recycling process of Li-ion batteries becomes more challenging.

Some of the main challenges in recycling lithium-ion batteries include:

There is a lack of global standards for recycling lithium-ion batteries.

The composition and percentage of lithium batteries are variable, and it is more difficult to directly recycle high-value materials such as positive and negative materials.

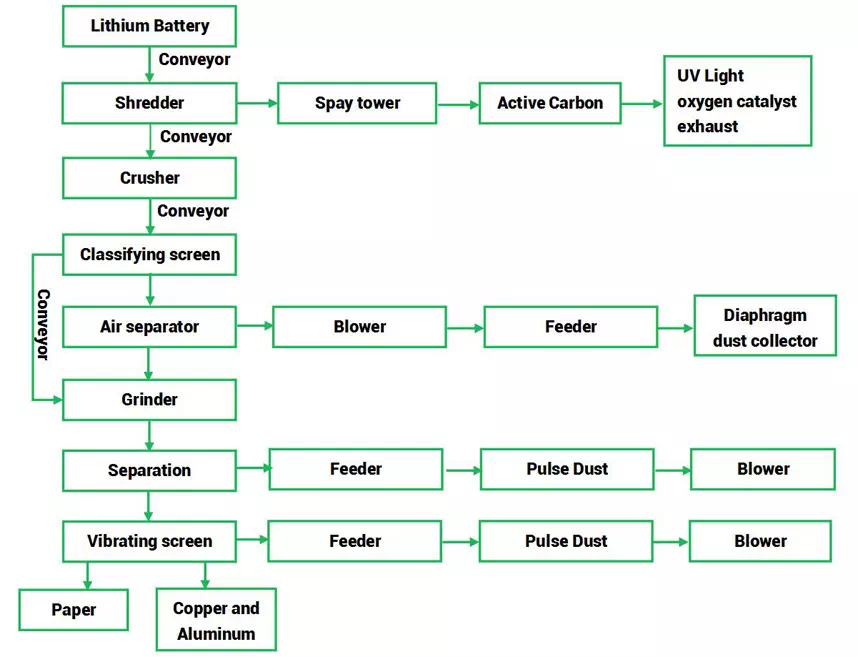

The disposal process of waste lithium-ion batteries is complicated, and requires an in-depth understanding of specific process conditions and special equipment configurations to make complete sets of equipment more environmentally friendly. SUNY GROUP has developed a complete waste lithium-ion battery treatment process plan and a complete set of waste lithium-ion battery crushing and sorting equipment. Using these processes and equipment, up to 95% of the valuable components in spent lithium batteries can be recovered, including the separation of case, copper, aluminum and black powder.

A lithium-ion battery recycling facility consists of several basic pieces of equipment, including:

Shredder: This system is used to tear large pieces of waste lithium batteries or some modules into small pieces for subsequent equipment to continue processing.

Shredder: This machine shreds old batteries into smaller pieces, making them easier to transport.

Pyrolysis systems: This technology is used to remove separators, electrolytes, organic materials and other contaminants.

Separator: This machine separates various materials, such as copper, from old batteries.

Separation system: used in various process links, the system separates black powder, shells, copper and aluminum combinations, etc.

Stripping system: The stripping system simultaneously separates copper-aluminum mixture, black powder and black powder on the separated copper-aluminum mixture.

Tail gas treatment system: The pyrolysis tail gas is discharged after being treated up to the standard.

One of the key innovations in lithium-ion battery recycling machines and systems is the dry process of used ion batteries. The whole process includes high-efficiency stripping, power generation controlled charged crushing, oxygen controlled pyrolysis, sorting, and environmentally friendly waste gas treatment.

Low cost and high efficiency: no discharge before recycling

Typically, used lithium-ion batteries store or retain electrical energy. In order to ensure the safety of the crushing process, brine or discharge is usually used. The discharge treatment is difficult, the discharge is not complete, and the cycle is long. This results in higher disposal costs and reduced economics.

SUNY GROUP waste lithium ion battery crushing and sorting equipment adopts an innovative design, so that lithium batteries do not need to be discharged before crushing. Ensure the safety and stability of the entire crushing process, and completely block the possibility of explosion, combustion and harmful gas diffusion. Therefore, the whole crushing process is safe, efficient and cost-effective.

·Wide processing range

The new lithium-ion battery recycling machine can be fully selected for recycling, and it can recycle all kinds of lithium batteries used by many mobile phones, laptops and other electronic equipment companies.

Lithium batteries are available in three packaging forms: cylindrical, square, soft and hard. Ternary batteries include lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, etc. SUNY GROUP has developed a complete set of crushing and sorting equipment for waste lithium-ion batteries, which can process all the above-mentioned types of batteries at one time.

SUNY GROUP has adopted a full-component, high-efficiency clean recovery process technology on the waste lithium-ion battery crushing and sorting equipment. This complete set of equipment can meet the centralized disposal of lithium-ion batteries of different systems and specifications to the greatest extent.

Under the protective atmosphere, the oxygen-controlled charging and crushing technology is used to overcome the environmental pollution caused by the long duration of the typical discharge and crushing process and the leakage of the electrolyte of the damaged battery. After crushing, the particle size of the product is uniform, the material is loose, and there is no wrapping phenomenon.

Under the protective atmosphere, the oxygen-controlled pyrolysis technology can choose to keep the diaphragm or pyrolyze the diaphragm. By pyrolyzing the separator, the electrolyte and binder molecular chains can be completely broken, providing a pretreatment solution for further process requirements.

To meet the necessary emission limits, the pyrolysis gases are systematically collected, fully catalytically oxidized, and then completely combusted.

The pyrolyzed material is sorted and stripped. Valuable metals such as copper, aluminum, and shells can be obtained, as well as high-quality black powder.

Li-ion battery recycling business is profitable as many companies have started using this type of batteries in their products. It is also a very successful business strategy as the demand for lithium-ion batteries is increasing and is expected to grow even more in the coming years.

Lithium batteries are widely used in electric vehicles and electronic devices. In recent years, the global demand for lithium batteries has grown significantly. However, the environmental damage caused by lithium batteries is also increasing. Therefore, it is necessary to recycle these old lithium batteries, which has become a new development direction for many factories.

As the lithium-ion battery market continues to grow and concerns about environmental issues increase, the demand for efficient and environmentally friendly lithium-ion battery recycling equipment and systems will continue to rise. Innovations in recycling technologies, increased compliance, and the development of global standards for lithium-ion battery recycling will play a key role in shaping the future of the industry.

The lithium-ion battery recycling business offers businesses and entrepreneurs a significant opportunity to contribute to environmental protection and resource conservation while generating profits. By staying informed about the latest technologies and best practices in lithium-ion battery recycling, businesses can seize these opportunities and contribute to a more sustainable future.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231